5 Tips for Optimizing CNC Efficiency with G-Code

Share

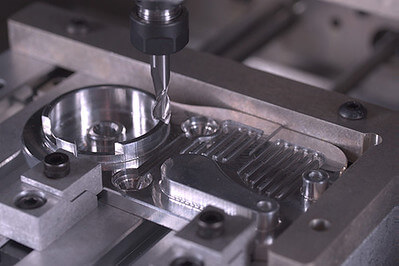

G-code, which stands for “geometric code,” is the programming language used by CNC machines. It is used to generate instructions for CNC machines to utilize when making physical parts.

There are five tips for enhancing CNC efficiency with G-code:

1. Use variables and subprograms to reduce redundancy and structure your program.

Variables allow you to save and reuse values in your G-code, such as part dimensions or tool feed rate. By avoiding the need to manually enter the same value several times, you can save time and make your program more efficient.

Subprograms enable you to bundle together related G-code commands and reuse them throughout your program. This can help to structure and make your program easier to read, as well as saving time by eliminating the need to write out the same series of commands many times.

2. G-code comments can be used to explain what each piece of your program performs.

Comments in G-code are lines of text that are disregarded by the computer and are used to provide explanations or remarks. They are indicated by a semicolon (;) at the start of the line. Commenting can help you and others understand the intent of each line of G-code and make troubleshooting any difficulties that may occur easier.

3. Optimize your toolpaths to reduce machining time and unnecessary movement.

The route taken by the tool as it sculpts or slices the material is known as the toolpath. you can cut down on machining time and unneeded movement. To do this, use the shortest instructions that are practical while avoiding abrupt turns and other pointless movements.

- Be familiar with your software feature Toolpaths.

- Face, Rought (Dynamic Mill, Opti-Rough and Opti-Rest)

- Face

- Finish

- Contour

- Air cutting – refers to the tool moving without actually cutting material.

- Know your machine’s capabilities.

4. Use G-code simulation.

G-code simulation is a way to virtually run the program on a computer before running it on the CNC machine. This can help identify any errors or issues in the program and can also be used to visualize and optimize the cutting path.

5. Create custom commands or variables with G-code macros that can be reused throughout your program.

Macros allow you to create custom G-code commands that can be reused throughout your code. This can save time and make your code more efficient by eliminating the need to write out the same sequence of G-code commands multiple times.

Macros can also make your program more organized and easier to read by allowing you to create short, descriptive commands that represent complex sequences of G-code.

For example, you could create a macro called “DRILL_HOLES” that represents a sequence of G-code commands to drill a series of holes in a specific pattern. Then, whenever you need to drill that pattern of holes, you can simply call the “DRILL_HOLES” macro instead of writing out the drilling commands each time.

You may also like

Optimizing CAD Designs for CNC Machining: Save Time and Money

Computer-aided design (CAD) plays a critical role in the manufacturing industry, and CNC machining is one of the most popular manufacturing processes that relies on CAD.

5 easy techniques for conquering tough machining operations

Complex machining refers to the production of parts and components with intricate shapes and high tolerances, and it often requires the use of a combination of different machining techniques and tools.

Ensuring Safety in the Fast-Paced World of Precision CNC Machining

CNC-machining is a process that involves technology to fabricate precise parts and components from various materials, such as Aluminum, Metals and Plastics. It is a highly